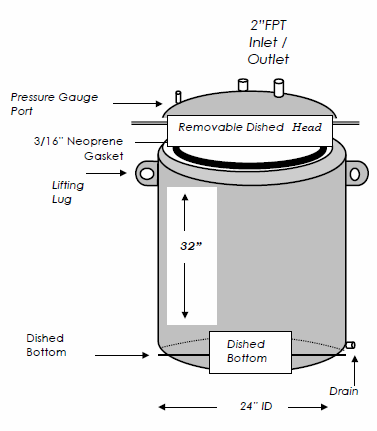

Medium Pressure Liquid Adsorber

Koko Coal India Medium Pressure 55 Gallon Adsober is designed for heavy-duty applications. The MP-55 is durable, strong, and intended for long-term use. Each unit comes equipped with lifting lugs, stainless steel bolts, a screened drain plug, and a pressure gauge port for monitoring your system operation. Each MP-55 adsorber is constructed of 12 gauge mild steel and is coated with coal tar epoxy on the inside and a 2-part epoxy on the outside.

| Specifications | |

| Diameter Inside Dimensions: | 24″ |

| Height, Outside Wall: | 32″ |

| Inlet Fitting: | 2″ FPT |

| Outlet Fitting: | 2″ FPT |

| Drain Fitting: | 1/2″ FPT |

| Carbon Weight: | 200 lbs. |

| Max. Recommended Flow Rate: | 15 GPM |

| Max. Pressure | 30 PSIG |

| Flow Direction | Downflow |

| Empty Bed Contact Time (EBCT) | 3.5 Minute |

Activated Carbon – The MP-55 liquid adsorbers are filled with virgin, high activity KC 8×30 activated carbon. Virgin KC 12×40 or other special carbons are also available.

Removable Dished Head – The removable lid is held in place with 20 stainless steel bolts through steel reinforced flanges. The gasket is made of 3/16″ thick neoprene.

Connections – Metal connections with standard pipe threads insure easy, durable, and leak proof hookup to your system. Unions or quick connect fittings are advised to make vessel exchange easy.

Flow Distributors – Both inlet and outlet have low pressure drop, slotted Schedule 40 PVC distributors. Units are designed to work downflow. Stainless steel internals are available for special applications.

Coatings – The MP-55 is coated with coal tar epoxy on the inside and a 2-part epoxy on the outside.

Installation & Startup – If possible before the units are used for the first time, they should be filled with clean water for a period of 8 to 12 hours to allow the carbon to degas. A gentle backwash is also recommended to remove carbon fines that can cause excessive pressure drop through the unit. Multiple units are usually connected in series with testing between the units advised to determine when the first unit needs to be changed out.

Maintenance – Once connected, the MP-55 requires no maintenance other than the monitoring of the influent and effluent liquid streams and the operating pressure of the system. Monitoring the liquid stream into the last unit in series mode is a recommended safeguard against breakthrough in the final outflow. When the concentration of contaminants in the outflow equals the concentration in the inflow, the MP-55 has reached its removal capacity and should be removed from service. The working life of each adsorber is dependent upon the type of contaminant in the water as well as its concentration and the liquid flow rate. A pressure relief device is advised to prevent damage to the vessel in the event of excessive pressure buildup.

Recharging the Carban – Once the carbon is saturated by contaminants, the unit should be removed and replaced with a fresh one. To purchase replacement carbon or to arrange for a carbon change-out, please contact our office.

Disposal – Dispose of the spent carbon in accordance with Local & State Law regulations.

CAUTION!

Wet activated carbon removes oxygen from air causing a severe hazard to workers inside carbon vessels. Confined space/low oxygen procedures should be put in place before entry is made. Such procedures should comply with all applicable Local & State Law.